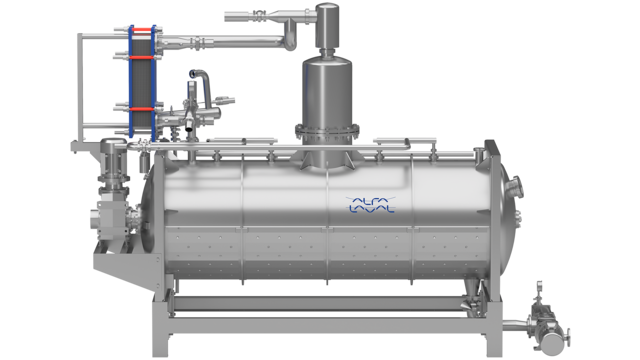

Olive Oil Booster

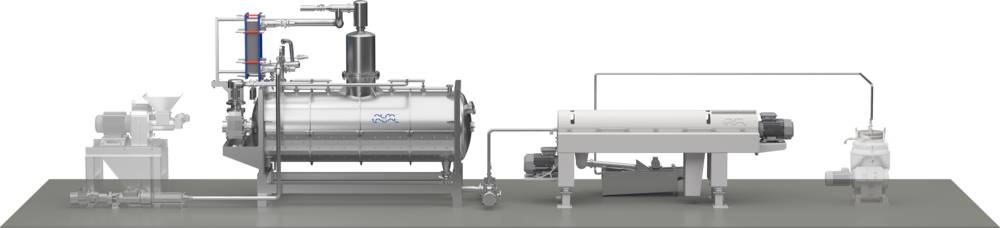

The Alfa Laval Olive Oil Booster is a combination of different technologies that work together for optimal results and increased revenue for the mills. Olive Oil Booster can maximize the yield of olive oil, while ensuring that the quality of the product is significantly improved compared to traditional technology. Thanks to Alfa Laval’s know-how, the Olive Oil Booster is also able to reduce water consumption and improve sustainability.

Achieving optimal yield and quality of olive oil all year round

- Maximizes oil yield throughout the harvest thanks to innovative technology combined with efficient processes

- Improves oil quality by increasing phenol extraction. This means healthier, longer-lasting oil with a higher retail value

- Improves sustainability with lower water consumption along with higher processing capacity

- Increases the amount of “free oil” released, improving the preparation of the paste and, in turn, the performance of the decanter

- Enhances the profit margins of the mill through higher yields, higher oil quality and reduced impact on operating costs

The Alfa Laval Olive Oil Booster helps mills bring a new era of profitability through a combination of efficient technology, higher productivity and lower water consumption. We know the challenges you face in an increasingly competitive market and we have designed a solution that can make your profits grow and your products stand out.

The Olive Oil Booster can fit perfectly in any olive mill and ensure that you get the most out of every stage of your olive oil production process. Simply put, the Olive Oil Booster is the best for your products, your profits and your environment.

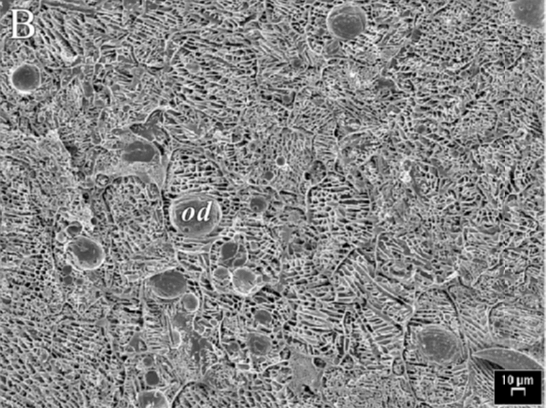

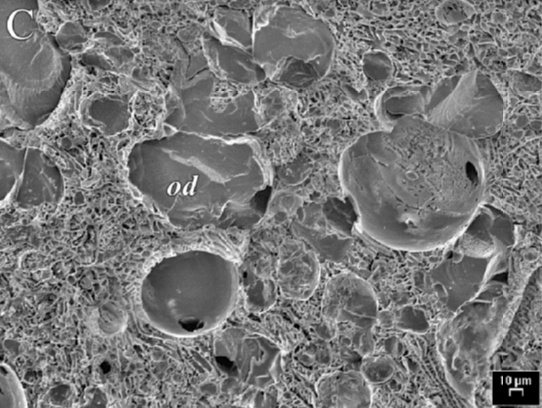

Magnified image of olive paste from an electron microscope. od = drop of oil

Figure B: After traditional massage

Figure C: After using the Olive Oil Booster

Excerpt from the scientific article “High vacuum-assisted extraction affects virgin olive oil quality: Impact on phenolic and volatile compounds” by Servili (2020) – “High vacuum extraction affects the quality of virgin olive oil: Effects on phenolic and volatile compounds” de Servili (2020)

How does it work

The Alfa Laval Olive Oil Booster system operates through a combination of thermal and separation solutions, with a plate heat exchanger (Plate Heat Exchanger – PHE) and a centrifugal decanter ( Sigma, X-series or Y-series ).

This makes the Alfa Laval Olive Oil Booster system a top-notch solution, while still being able to maintain the traditional process flow, as can be seen by following the step-by-step summary below:

Step 1 – The crushed olive paste is introduced into the booster

The olives are crushed as is done in traditional olive mills. The olive paste is immediately transferred to the Olive Oil Booster at a specified vacuum pressure. Thanks to the vacuum pressure, there is a rapid cooling process and rapid removal of oxygen.

Step 2 – Release “without oil” from the olive paste

The olive paste is stirred from the horizontal axis with blades for a certain time at a constant pressure (deep vacuum) and temperature. By maintaining the vacuum pressure below the boiling pressure at a constant temperature (i.e. 18 ° C), the olive paste is maintained at boiling conditions where a certain amount of water changes its natural phase from liquid to steam. This process of boiling olive paste in a cold state is able to produce more oil extraction and a higher amount of “free oil” rich in phenol compared to traditional massage, with a significant increase in the yield of olive oil in higher quality. The energy required for this natural phase change is provided by hot water circulating in the vacuum tank cap, heating the olive paste.

The olive paste is stirred from the horizontal axis with blades for a certain time at a constant pressure (deep vacuum) and temperature. By maintaining the vacuum pressure below the boiling pressure at a constant temperature (i.e. 18 ° C), the olive paste is maintained at boiling conditions where a certain amount of water changes its natural phase from liquid to steam. This process of boiling olive paste in a cold state is able to produce more oil extraction and a higher amount of “free oil” rich in phenol compared to traditional massage, with a significant increase in the yield of olive oil in higher quality. The energy required for this natural phase change is provided by hot water circulating in the vacuum tank cap, heating the olive paste.

The small amount of steam produced when the olive paste is exposed to vacuum is concentrated by a plate heat exchanger, where cold water is produced by a refrigeration unit and the small amount of steam condensate is returned to the extraction process. Because the paste boils at a low temperature, there is no negative effect on the amount of positive aromatic compounds in olive oil.

This “free oil” release step could be achieved entirely by the Olive Oil Booster, or by using the Booster in combination with traditional massage .

Step 3 – Separate the olive oil with a centrifugal decanter

The olive paste prepared by Olive Oil Booster is fed to the centrifugal separator (decanter) where the oil is separated from the water and the solids, in two or three phases.

The performance of the decanter in terms of capacity, oil clarity, residual oil in the skin and the amount of dilution water (in case of three phases), depends strictly on the characteristics of the olive paste prepared during the previous process.

With a traditional massage system, the results of “free oil” production and the oil extraction dimension depend strictly on many variables such as olive ripening, olive fruit moisture, olive variety, crushing technology, etc. The preparation of olive paste carried out by Olive Oil Booster has been improved in terms of olive oil extraction dimensions and the production of “free oil” in relation to the traditional method. This improvement is achieved regardless of the characteristics of the fruit compared to the traditional method.

All this leads to a significant improvement in the separation efficiency of the decanter with clear advantages in reducing the residual oil in the skin, increasing the yield capacity, improving the clarity of the olive oil and reducing the amount of dilution water when used. The improved clarity of the oil obtained from the decanter, after the Olive Oil Booster, also helps to improve the efficiency of the vertical centrifugal separator for cleaning the olive oil. The oil coming from the decanter with less impurities improves the vertical centrifugation capacity and reduces the number of cleaning stops.